Description

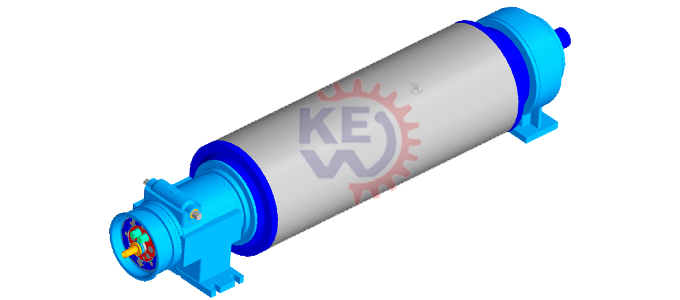

We are dealing on Suction Roll from last 25 years from India, It allows us to design & supply all kinds of Suction Rolls. Also, dealing to supply complete Suction Roll Assemblies. Enabling features like end deckle adjustment, water connection for lubricating shower, air connection for tail feed and seal loading, suction box positioning, bearing lubrication fittings, and many more.

Suction Rolls are designed to reduce moisture, eliminate crush and generally improve mill productivity. We have over 12 years experience manufacturing the highest quality suction rolls. We have designed and built rolls ranging from non-driven fixed opening suction felt rolls to variable width, variable length suction forming rolls. The experience and manufacturing expertise gained over this period assures a modern and efficient roll that will stand the test of time.

Technical Specification

Suction Roll

Prior to delivery all our Suction Rolls are thoroughly inspected using the latest state-of-the-art computer programs. This not only assures the integrity and strength of the roll, but also that it will provide the highest level performance in the nip with your geometry.

– The shell is centrifugally cast out of various bronze and stainless steel alloys. The metallurgy that is right for your specific application depends on the mill’s environment. All shells are drilled on a spiral pattern to assure quite operation.

– The suction box features stainless steel fabrication, and is counterbalanced to offset the seal arrangement and support the box during removal.

– The stainless steel features a bolt-on design and is sized to provide the optimum velocity while reducing noise and preventing premature separation.

– The forged steel heads are epoxy painted to prevent corrosion.

– A box adjustment of 360- rotation is provided by a full worm gear and worm.

– There is a three bearing design with the rear internal bearing featuring an inner ring rotation. The entire rear internal bearing assembly is replaceable.

– Deckle adjustment is made from the front of the roll utilizing a dual shaft arrangement.

Standard Features

We produce these rollers in standard sizes and also cater to the needs of customizes S.S. Rollers for the ease of our customers. We can alter the shape, size and designs of these rollers. We offer to our clients superior range of Suction Roller that are known for their efficient performance and resistance against corrosion. The use of superior engineering in its manufacturing makes them function more smoothly and quietly. Selection of roller type and coating material depend upon the application and the web material. “Krishna Engineering Works” manufactures wide range of S.S rollers for varied applications.

Application

- Roller used in Different Machines for Plastic Industry : Printing Machine, Flexible Printing Machine, Flexo Machine, Lamination Machine, Graver Machine, Scaling Machine, Pipe Plant, Winding Unwinding Machine, Offset Printing, Box Strapping Machine

- Roller used in Different Machines for Textile Industry : Stenter Machine, Jigger Machine, Rotary Machine, Dyeing Machine, Calender Machine, Mangle Machine, Loop Steamer

- Used in Different Industries : Industries like, Paper, Pharmaceuticals, Leather, Textile, Plywood, Sheet Line, Material Handeling and many more.

Our equipments are used for following Applications:

- Rewinding – Converting, Textile, Paper, Tire,

- Unwinding – Converting, Textile, Paper, Tire,

- Marking, Coding and Printing Applications,

- Slitting – Any type of Laminate,

- Packaging,

- Wrapping,

- Printing – Converting and Textile,

- Tracking,

- Controlling Tension & Edge of Laminate / Fabric.