Description

Krishna Engineering Works dealing to meet International standard for Calendar Roller with high quality and reliability for high production. We are also dealing on calendar roll disassembly / assembly, Calendar roll inspection, Calendar roll grinding and super finishing, Calendar roll refurbishment and many more.

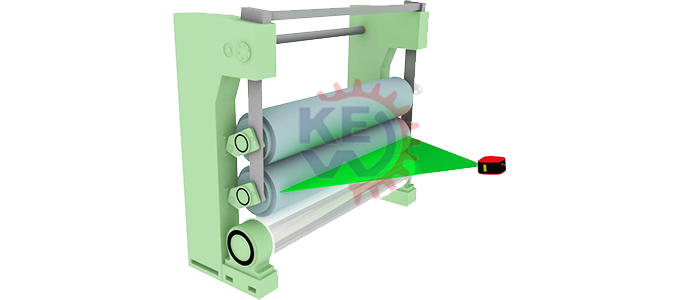

In the calendering process, precision rolls are used in order to guarantee that the final product has optimum properties. The rolls used for these purposes must meet extremely high standards. Calender rolls of maximum precision with respect to geometry, runout and surface finish are supplied for use in your continuous duty application.

Our rolls are manufactured to comply exactly with customers’ specifications. They are designed and produced in close cooperation with the end user. Structural and thermal stresses are controlled by roll design and manufacturing experience. Rolls are fully inspected. Each manufacturing step is documented, because complete quality assurance is a matter of course. Research and development are considered as means of constant improvement of materials, processes and service.

Technical Specification

Calendar Roll

We can offer rolls made from various materials:

– Chilled cast iron (single poured)

– Chilled cast iron with nodular cast iron core (compound casting)

– Grey cast iron

– High chrome-alloy special cast iron

Standard Features

Our rolls are manufactured using modern CNC machines at all manufacturing stages, maximum precision is guaranteed with respect to cylindricity, roundness, concentricity and surface quality. Besides cylindrical barrel grinding all types of crowns, as well as special roll profiles, are possible. Rolls can be furnished with a matt, engraved or corrugated finish.

Using oil or water heating systems, roll grinding temperatures of up to 300 -C can be achieved. This ensures maximum precision for the roll when it is heated up to operation temperature. Our expertise, which is the result of continuous research and development in the field of super finishing, even allows us to produce rolls with a flawless mirror finish.

Application

- Roller used in Different Machines for Plastic Industry : Printing Machine, Flexible Printing Machine, Flexo Machine, Lamination Machine, Graver Machine, Scaling Machine, Pipe Plant, Winding Unwinding Machine, Offset Printing, Box Strapping Machine

- Roller used in Different Machines for Textile Industry : Stenter Machine, Jigger Machine, Rotary Machine, Dyeing Machine, Calender Machine, Mangle Machine, Loop Steamer

- Used in Different Industries : Industries like, Paper, Pharmaceuticals, Leather, Textile, Plywood, Sheet Line, Material Handeling and many more.

Our equipments are used for following Applications:

- Rewinding – Converting, Textile, Paper, Tire,

- Unwinding – Converting, Textile, Paper, Tire,

- Marking, Coding and Printing Applications,

- Slitting – Any type of Laminate,

- Packaging,

- Wrapping,

- Printing – Converting and Textile,

- Tracking,

- Controlling Tension & Edge of Laminate / Fabric.