Description

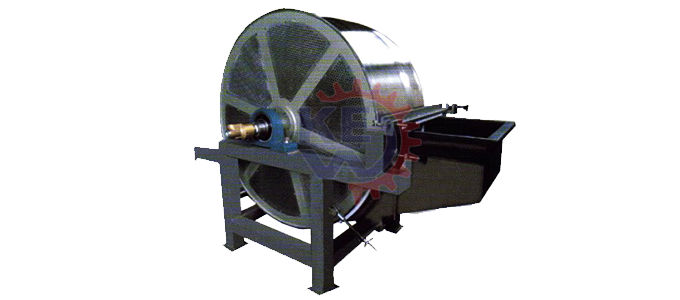

We have been manufacturing Cooling Drum from stainless steel with drum dimensions. 100% of product is solidified, flaked, and recovered. Suitable for food, chemical, and pharmaceutical industries. Our cooling Drum is featuring like, high quality steel for high performance and drum flaking is the most efficient method for solidification and flaking of a wide range of materials per client’s requirement and application.

Cooling Drum have hard chrome plated surface. Cooled water passing through its Rotary joint to cools the hard chrome plated surface area of the Roll. Cooling Roll cools the contact area that touches the web materials or rubber rolls. There are different type Cooling Rolls like single shell, double shell jacketed type, spiral type. The surface cooling effect will be varying for different types. Cooling Roll having shaft with inside hole to fix rotary joint. Bigger shaft diameter is recommended to avoid breakage of end shafts as end shaft having inside hole.

Technical Specification

Cooling Drum

Prior to delivery all our Cooling Drum are thoroughly inspected using the latest state-of-the-art computer programs. This not only assures the integrity and strength of the roll, but also that it will provide the highest level performance in the nip with your geometry.

– The shell is centrifugally cast out of various bronze and stainless steel alloys. The metallurgy that is right for your specific application depends on the mill’s environment. All shells are drilled on a spiral pattern to assure quite operation.

– The suction box features stainless steel fabrication, and is counterbalanced to offset the seal arrangement and support the box during removal.

– The stainless steel trunnion features a bolt-on design and is sized to provide the optimum velocity while reducing noise and preventing premature separation.

– The forged steel heads are epoxy painted to prevent corrosion.

– A box adjustment of 360- rotation is provided by a full worm gear and worm.

– There is a three bearing design with the rear internal bearing featuring an inner ring rotation. The entire rear internal bearing assembly is replaceable.

– Deckle adjustment is made from the front of the roll utilizing a dual shaft arrangement.

Standard Features

We offer a range of cooling drums for Textile Industry which are customized according to the clients specifications. This cooling drum is made of high quality material to ensure quality standards across the globe and its effective functioning. Our quality standards are a priority which cannot be ignored to maintain good reputation among our valued clients.

We are engaged in manufacturing and supplying of cooling drums which are highly effective and of great importance for paper industry. This is made of high quality material which ensures its durability and resistance to corrosion. These cooling drums are safe to use, require low maintenance and reliable and this has helped us to gain a reputation in the international market. We manufacture products according to specific requirements of our valued clients with superior quality of material.

Application

- Roller used in Different Machines for Plastic Industry : Printing Machine, Flexible Printing Machine, Flexo Machine, Lamination Machine, Graver Machine, Scaling Machine, Pipe Plant, Winding Unwinding Machine, Offset Printing, Box Strapping Machine

- Roller used in Different Machines for Textile Industry : Stenter Machine, Jigger Machine, Rotary Machine, Dyeing Machine, Calender Machine, Mangle Machine, Loop Steamer

- Used in Different Industries : Industries like, Paper, Pharmaceuticals, Leather, Textile, Plywood, Sheet Line, Material Handeling and many more.

Our equipments are used for following Applications:

- Rewinding – Converting, Textile, Paper, Tire,

- Unwinding – Converting, Textile, Paper, Tire,

- Marking, Coding and Printing Applications,

- Slitting – Any type of Laminate,

- Packaging,

- Wrapping,

- Printing – Converting and Textile,

- Tracking,

- Controlling Tension & Edge of Laminate / Fabric.